Product Description

HS Series Premium PDC Bit

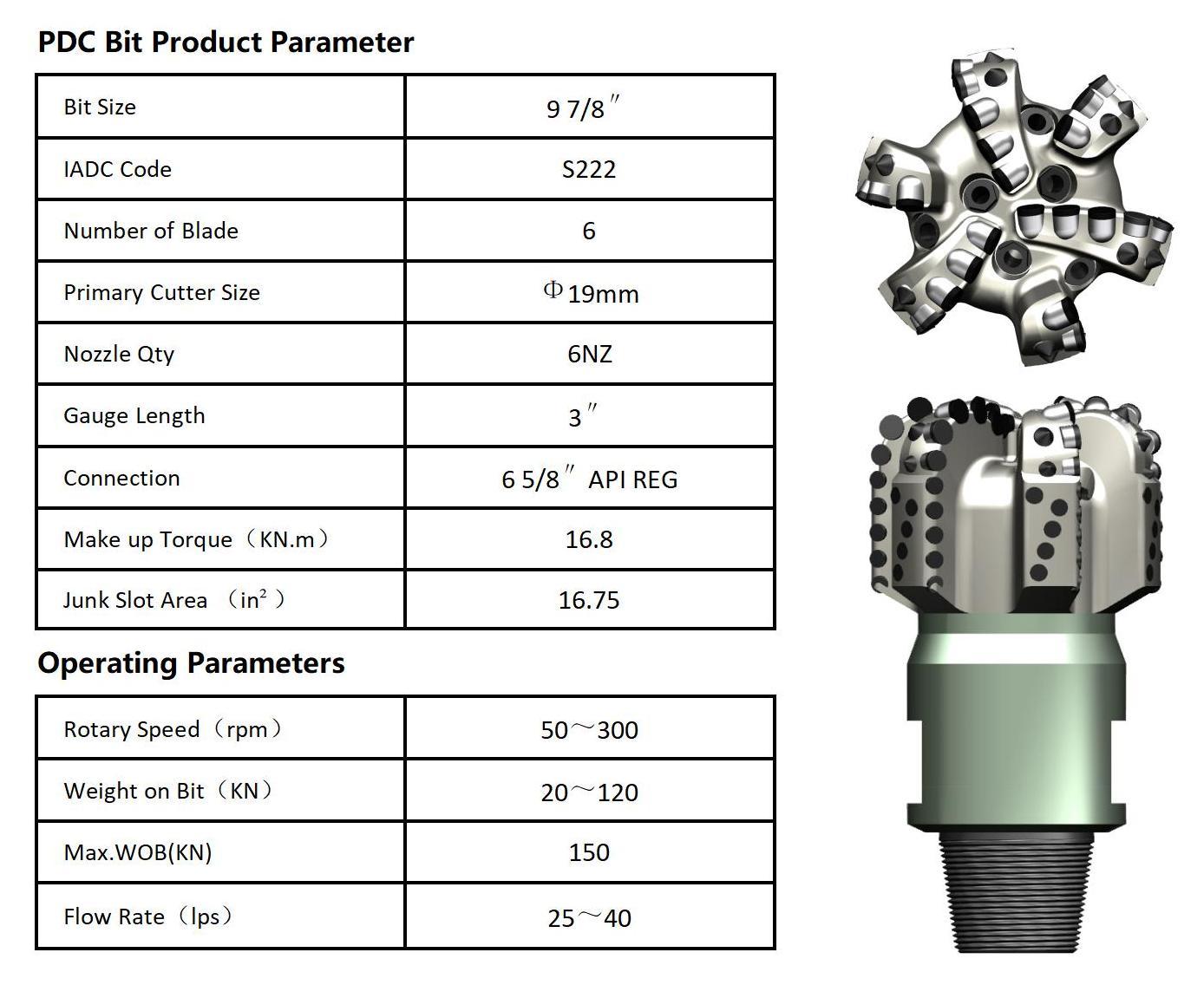

HS series PDC bit is tough and durable drilling tool, the mechanically simple fixed cutter designation allows it to go through complicated HDD drilling project and super deep vertical oil well drilling with unrivalled speed and boring quality . It has been proven over hundreds of working cases, HS series is designed and built to the highest engineering and manufacturing standards by Precise Drilling Materials and Components.It’s our Premium Quality PDC tools. HS Series fixed cutter PDC bit is API7-1 and ISO9001-2015 standard and available in sizes ranging from 4 1/2” to 17 1/2”.

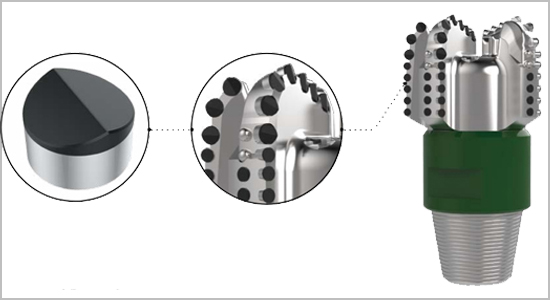

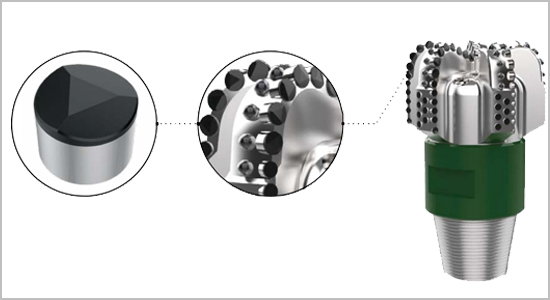

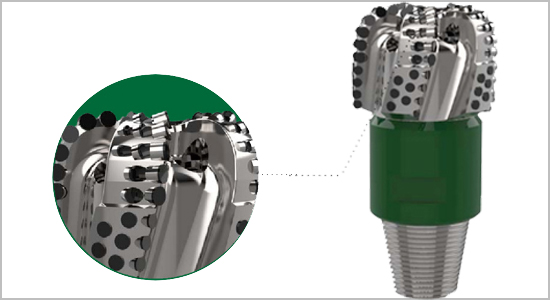

PDC Drill Bit Structure

Patented axe-shaped gear, it adopts comprehensive substrate design to ensure the impact of the product,if forms the best contact point to obtain the best drilling effect.it has high rock-breaking efficiency,low cutting resistance,and can be directed to cutting removal.it has higher impact resistance and mud pack resistance than the plane composite sheet.the cutting ridge line is conductive to digging into the ground,which has higher cutting efficiency.

Patented benz gears.it can form the best contacting point and get the best drilling effect.it has high rock -breaking efficiency,low cutting resistance,and can be directed to cutting removal.it has higher impact resistance and mud pack resistance than plane composite sheet.the cutting ridge line is beneficial to drill into the stratum,which has higher cutting efficiency and longer service life than flat one.it can adopt different substrates according to different stratum.

Inclined blade design to increase the stability of the drill bit and improve the taper rate.

Features and Applications

|

Steel body PDC bit using tiny arc-type double rows five spiral blades asymmetric and Medium paraboliccrown design with different structure patent cutters are laid out at different location of the bit to ensure its high aggressi-veness and long bit life .Effectively improve the rate of speed .Dynamic flow simulating technology is used for hydraulicdesign to ensure optimum bottom hole flow patters and anti-balling . Medium soft to hard formations with high compressive strength and abrasive ,such as Mudstone, L.imestone, Anhydrite,Sandstone and so on. |

What Kind of PDC Bit is Suitable

Well Drill PDC Bit Types

Steel Body PDC bit

These steel bodied bits have advanced hydraulics and forward advanced blades that significantly increase ROP. The bits are specifically designed to increase productivity in sandstone and shale formations. They are customizable with flushing holes and fixed or adjustable nozzles,along with blade count and diamond cuter size configuration options.

Matrix Body PDC bit

The matrix body PDC bits provide a stronger wear resistance due to the matrix powder that is applied to the body. The matrix body style is able to withstands harder compositions,such as dolomite and limestone. Bits are fully customizable with flushing holes and fixed or adjustable nozzles,along with blade count and diamond cutter size configuration options.

PDC Center Drill Bit

Main Applications:PDC bit can be customized for oil well,water well, mining, explorer well drilling.

Suitable Formation :Various of hardness rocks or mud except the hardest hardness or ununiform rocks like cobble.

Main Features: 1.Bit Diameters: 3"~22" etc.2.Body Type: Matrix or Steel4.3.Cutter Sizes:5/16"(8mm),1/2"(13mm),5/8"(16mm),3/4"(19mm),etc.

4.Blades:3~9 Wings.

PDC Matrix Body Core Bit

Main Applications :PDC core bit can be customized for oil well,water well, mining, explorer well drilling.

Suitable Formation: Various of hardness rocks or mud except the hardest hardness or ununiform rocks like cobble.

Available Size: 75/54mm,94/74mm,113/89mm,113/109mm,153/129mm,215/105mm,etc.

PDC Drill Bit Packages By Air /By Sea

Related Diamond PDC Bits /Products

Urumqi Siruite Mechanical Equipment Co.,Ltd

Urumqi Siruite Mechanical Equipment Co.,Ltd