Urumqi Siruite Mechanical Equipment Co.,Ltd

Urumqi Siruite Mechanical Equipment Co.,Ltd

URUMQI SIRUITE MECHANICAL EQUIPMENT CO., LTD

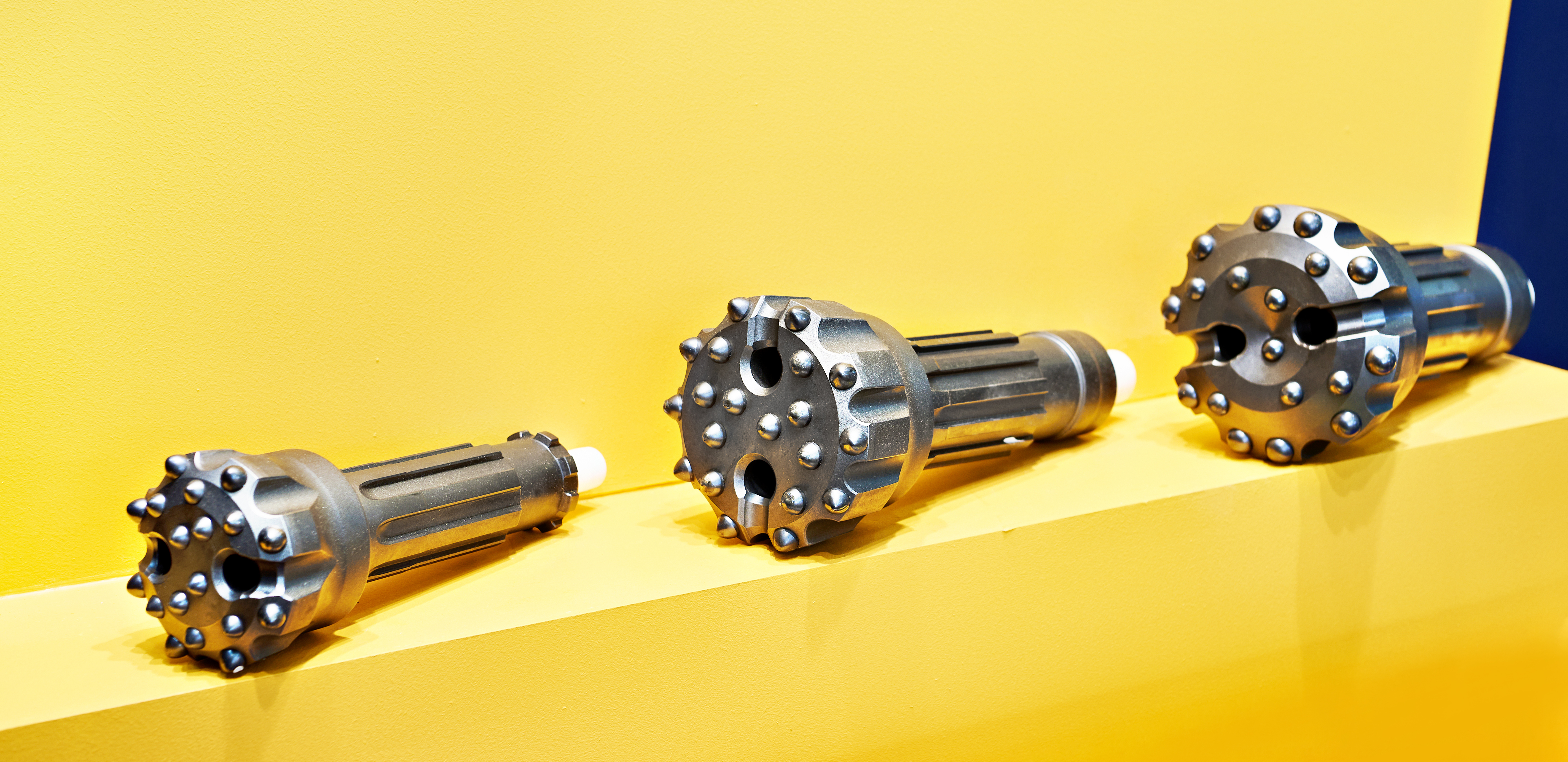

DOWN THE HOLE (DTH HAMMER & BITS)

DTH HAMMER is a kind of pneumatic rock drilling tools, the difference from others is during drilling process hammer always stay in the bottom of the hole, impact the rock by bit from hammer directly. High pressure air enter into the hammer through drill pipe, then run out from drill bits, exhaust air are used to blow up cuttings from the bottom of hole. The rotating power acting on DTH hammer comes from rotation motor on the drill rig, the pull force comes from feeding device and transfer the energy to hammer through drill pipe.

How Does DTH Hammer Work

1.Drilling bit press against the rock.

2.High pressure air burst through the check valve from drill pipe and enter the front cavity of hammer.

3.The increase of the front cavity volume pushes the piston to move upward.

4.When piston moves up to a certain extent, the front cavity deflates and the compressed air enters into the back. Piston keeps moving upward because of inertia.

5.When the piston to a certain extent, due to the compression of the back cavity and the increase of air pressure, the piston starts to impact downward which forming an impact stroke. Moves up circles as the above process to achieve impact and complete rock drilling.

Types of DTH hammer

1.Group by hammers cutting blowing up way: Conventional DTH hammer & Reverse Circulation DTH hammer (RC hammer).

2.Group by hammers air distribution and structure characteristics: Hammers with valve & Hammers without valve.

3.Group by hammers rated working pressure:

a.Low air pressure DTH hammer(rated working pressure W 0.7Mpa),

b.Mid-Low air pressure DTH hammer(0.7Mpa< rated working pressure W 1.5Mpa ),

c.High air pressure DTH hammer(1.5Mpa< rated working pressure/ 2.5Mpa),

d.Ultrahigh air pressure DTH hammer (rated working pressure>2.5Mpa)

4.Group by the assorted bit which with or without foot valve: DTH hammers available for assorted bit which with foot valve & without foot valve.

5.Group by hammers OD: 1 inch, 2 inch, 3 inch, 4 inch, 5 inch, 5.5 inch, 6 inch, 7 inch, 8 inch, 9 inch, 10 inch, 12 inch ,15 inch, 24 inch, etc.

Applications of DTH Hammer

DTH hammers are widely used in geological exploration, ore mining, water well drilling and construction foundation project.

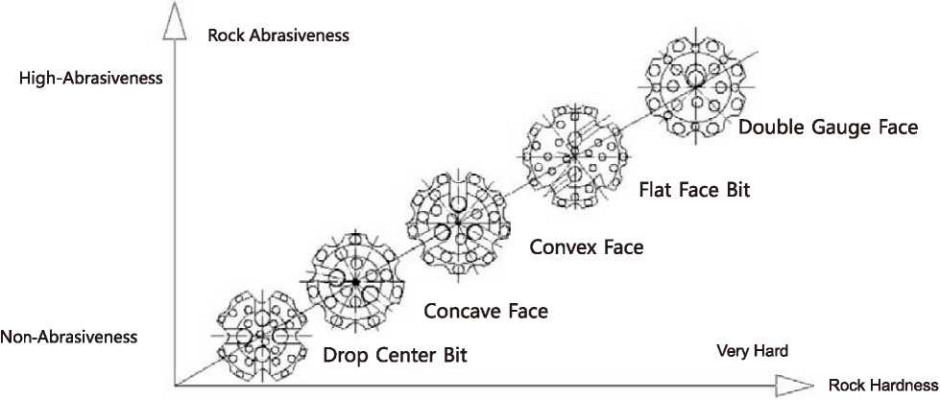

Bit Face Shape Selection

Drop Center Face :for high penetretion rates and minimum hole deviation in soft to medium hard and fracture rock formations.

Concave Face: suitable for all application ground special for medium hard and homegeneous rock formations. good hole deviation control and good flushing capacity.

Convex Face: suitable for soft to medium-hard rock formation with low to medium air pressures.it is the most resistance to steel wash,and may reduce the load and wear on the gauge buttons,high penetration rate but poor hole deviation control.

Flat Face: this kind of face shape is suitable for very hard and abrasive rock formation in application with high air pressures.good penetration rate and resistance to steel body.

Double Gauge Face:this kind of face shape is suitable for high air pressure drilling in medium to hard rock formations. designed for high penetration drilling with good resistance on steel body.

Carbide Button Shape Options

Round Button:usually used as gauge buttons of DTH Bits, suitable for very abrasive and very hard formations.

Ballistic Button:used as front buttons of DTH Bits, suitable for medium abrasive and medium hard formations.They can also be used as gauge buttons if the rock is soft.

Parabolic Button:used as gauge buttons and front buttons of DTH Bits, suitable for medium abrasive and hard formations.

Conical Button : usually used as front buttons of DTH bits for soft formations providing fast penetration rates and I low risk of button break.

Flat Button :used as protection buttons to against wear on surfaces of DTH Bits.

Technical Parameters Reference Table

The Main Characters Of High Air Pressure DTH Hammers

DTH Bit With Footvalve

1.Valveless air distribution. More reliable.

2.Simple design of the piston, long life.

3.Fewer internal parts, simple structure, longer life, less failure and easier to maintain because all spare parts are hardened.

4.Easy to disassembly because the top sub, and the drive chuck are connected with external cylinder with a multi-step thread.

DTH Bit Without Footvalve

1.Out of the trouble of foot valve fracture caused by expansion and contraction.

2.Lower energy consumption and higher impact frequency. The drilling speed is 15%-30% faster than similar bits but with foot valve.

3.Simple structure, reliable parts, long life, easy maintenance with low cost.

4.Lower air and diesel consumption. The diesel consumption is about 10% lower than the bits but with foot valve.