Urumqi Siruite Mechanical Equipment Co.,Ltd

Urumqi Siruite Mechanical Equipment Co.,Ltd

URUMQI SIRUITE MECHANICAL EQUIPMENT CO., LTD

Roller Cutter and Tools Quality Levels: BASIC / STANDARD / PREMIUM

Tricone bit rollers are a type of cutting element used in tricone bits for HDD (Horizontal Directional Drilling) hole openers. These rollers are designed to cut through hard rock formations and provide several advantages over other types of cutting elements.

The main advantage of tricone bit rollers is their ability to withstand high levels of stress and wear during drilling. The three cone design allows for even distribution of the load, which reduces the risk of damage or failure. Additionally, the use of high-quality materials such as Tungsten Carbide Inserts (TCI) or Polycrystalline Diamond Compact (PDC) further increase the durability and longevity of the rollers.

Another advantage of tricone bit rollers is their ability to maintain a consistent size and shape throughout the drilling process. This is important when drilling large diameter holes with HDD hole openers, as any deviation from the intended size and shape could cause problems with the installation of pipes or cables.

Tricone bit rollers also offer better cutting speed and efficiency compared to other types of cutting elements. The multiple teeth on each roller allow for more contact points with the rock formation, which increases the cutting action and reduces the time required to drill through the formation.

Finally, tricone bit rollers can be easily replaced or repaired when necessary, reducing downtime and increasing productivity on drilling projects.

In summary, tricone bit rollers are an effective and efficient cutting element for HDD hole openers. Their durability, consistency, cutting speed, and ease of maintenance make them a popular choice for drilling in challenging rock formations.

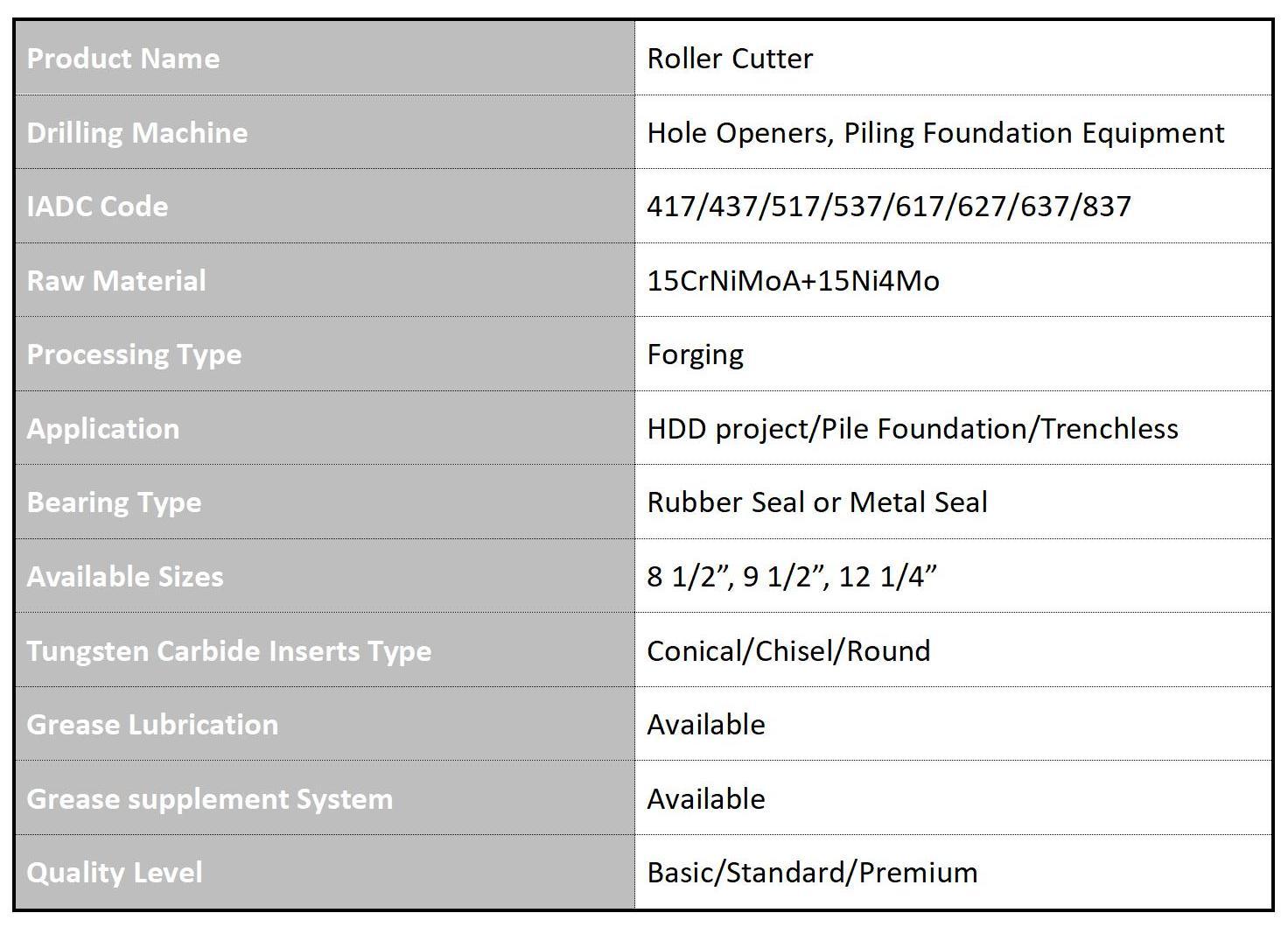

Roller Cutter Main Parameters

Roller Cone's Installation Tips on Foundation Core Barrel