URUMQI SIRUITE MECHANICAL EQUIPMENT CO., LTD

URUMQI SIRUITE MECHANICAL EQUIPMENT CO., LTD

SIRUITE DRILLING TOOLS LIMITED

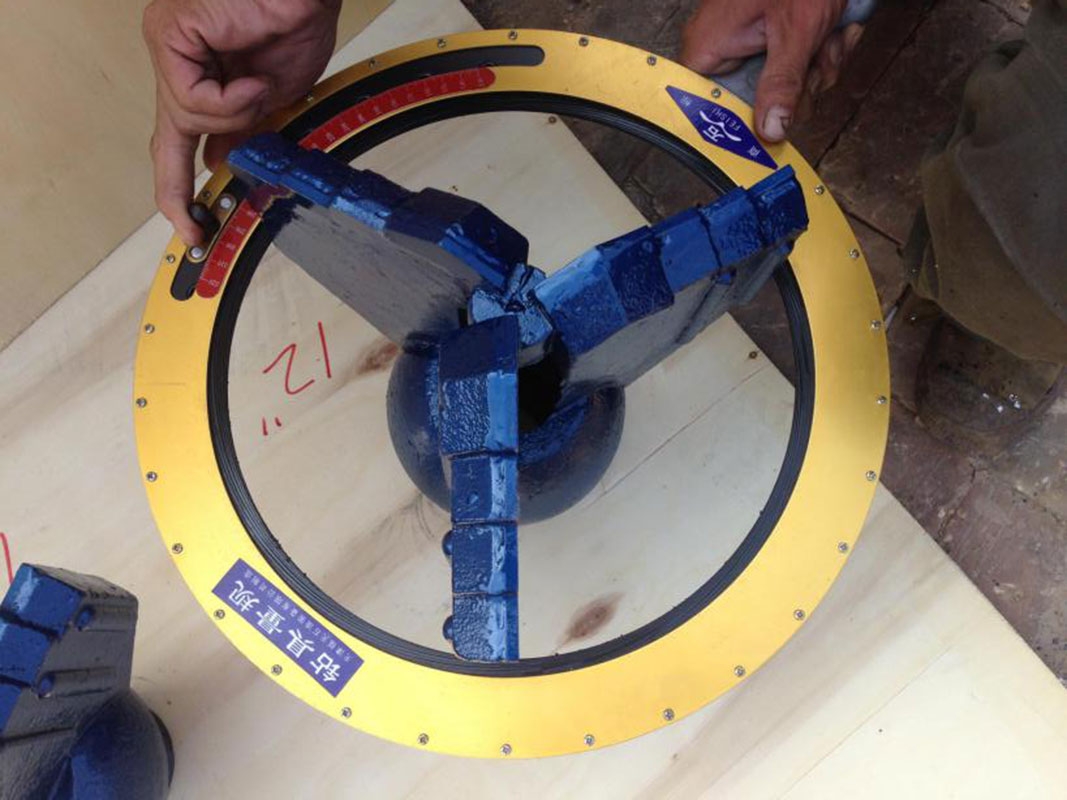

What is Drag Bit Drag bits are also named blade bits, with a TC inserts on the blades which manufactured from forged high quality alloy steel and premium tungsten carbide insert, plus state of art welding technology and multiple precision heat treatment to provide highest penetration rate and longest lifespan at roughest condition.There are several types of drag bits that each have they’re own purpose and are better at certain types of drilling than others. For example drag bits are not ideal for hard rock formations or coarse gravel; but their uses for exploration and environmental drilling are well documented and their most common job.

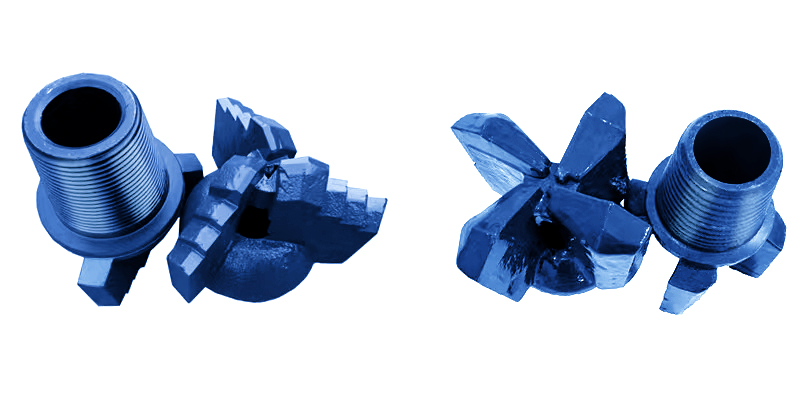

Two Types of Drag Bit

Step Drag Bit: Bits are primarily designed for rapid penetration in soft to medium formations such as clay,sand rock or shale.Step bits are available with regular and heavy steps.Heavy steps are recommended for harder formations.They feature more cutting carbides and offer increased durability.

Chevron Drag Bit: Bits are designed for harder,more consolidated formations such as hard shale or limestone,areas with rock, and for drilling out concrete casings and plugs.The chevron type drag bit does not penetrate as fast as the step type,but will cut harder formations. As a general rule three wings bits offer faster penetration,whereas four wings bits offer increased .

Drag Bit ApplicationDrag bits are economical tools when drilling softer geological formations and shallower deepness when the DTH hammer and tricone bit

lose their effectiveness.They have a wide range of uses from geothermal and waterwell drilling to road construction, underground water, natural gas and everything in between. Whenever possible, they should be used to drill pilot holes, for they produce cuttings that are easiest to log.Siruite is a professional supplier of drag bits in China, we supply both step drag bits and chevron drag bits with 3 or 4 wings. Step drag bits are usually used for drilling overdurdens with sands, clays,shale,soft limestones and some other soft formations. Compared with chevron drag bits, step drag bits produce large cuttings and more aggressive, however, will be less durable.