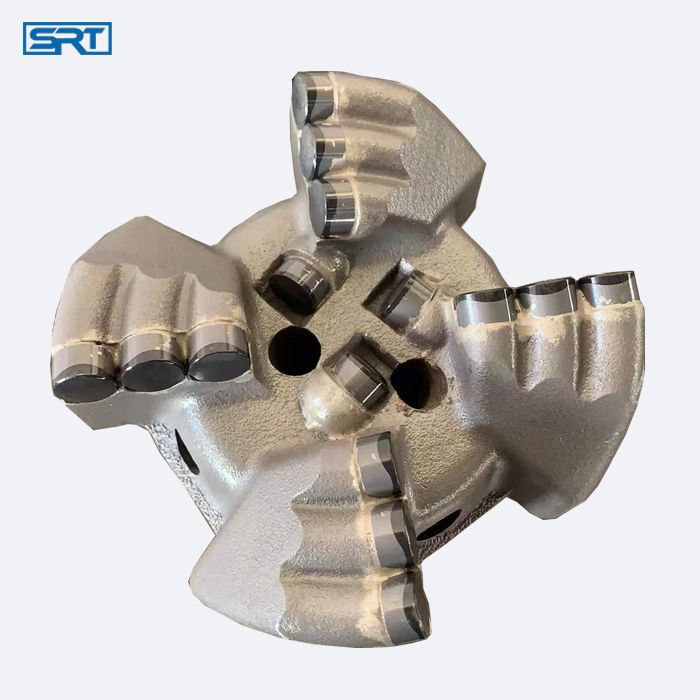

SST Series Tricone Drill Bit

The teeth of SST series Wear resistance is enhanced with premium tungsten carbide hardfacing. on the tooth surface, for steel tooth bit.The well comprehensive mechanical drilling performance of premium tungsten carbide inserts is improved with new formulas and new techniques . Multiple gauge protection inserts with gauge trimmers on the gauge surface of the cone,tungsten carbide inserts and hardfacing on the shirttail increases gauge holding capability and bearing life.high precision journal bearing with two thrustfaces.Balls lock the cone .Hardfaced head bearing surface.Cone bearing inlaid with friction-reducing alloy and then silver-plated.Abrasion resistance and seizure resistance of the bearing are improved,and suitable for high rotary speed. Ball lock cones, which optimize the R slot size of tooth and cone and the tolerance clearance of steel ball ,to prevent rock falling off efficiently.

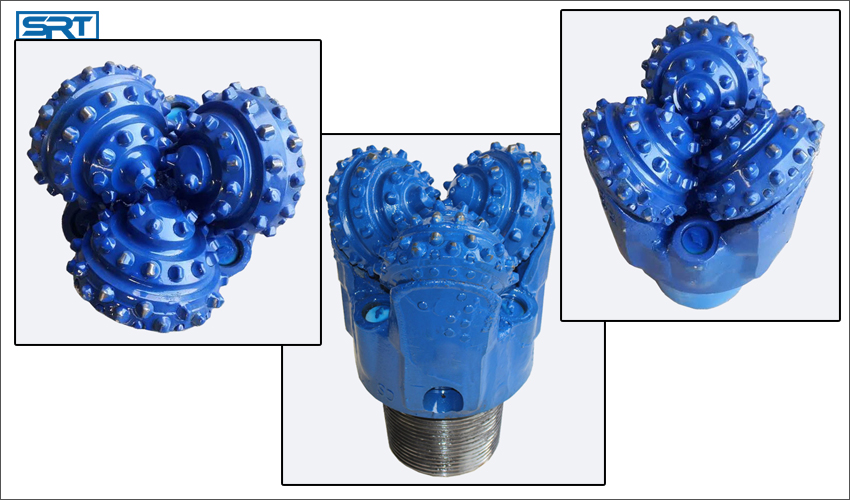

Water Borehole Drilling CS 9 7-8 Carbide Button TCI Tricone Bits

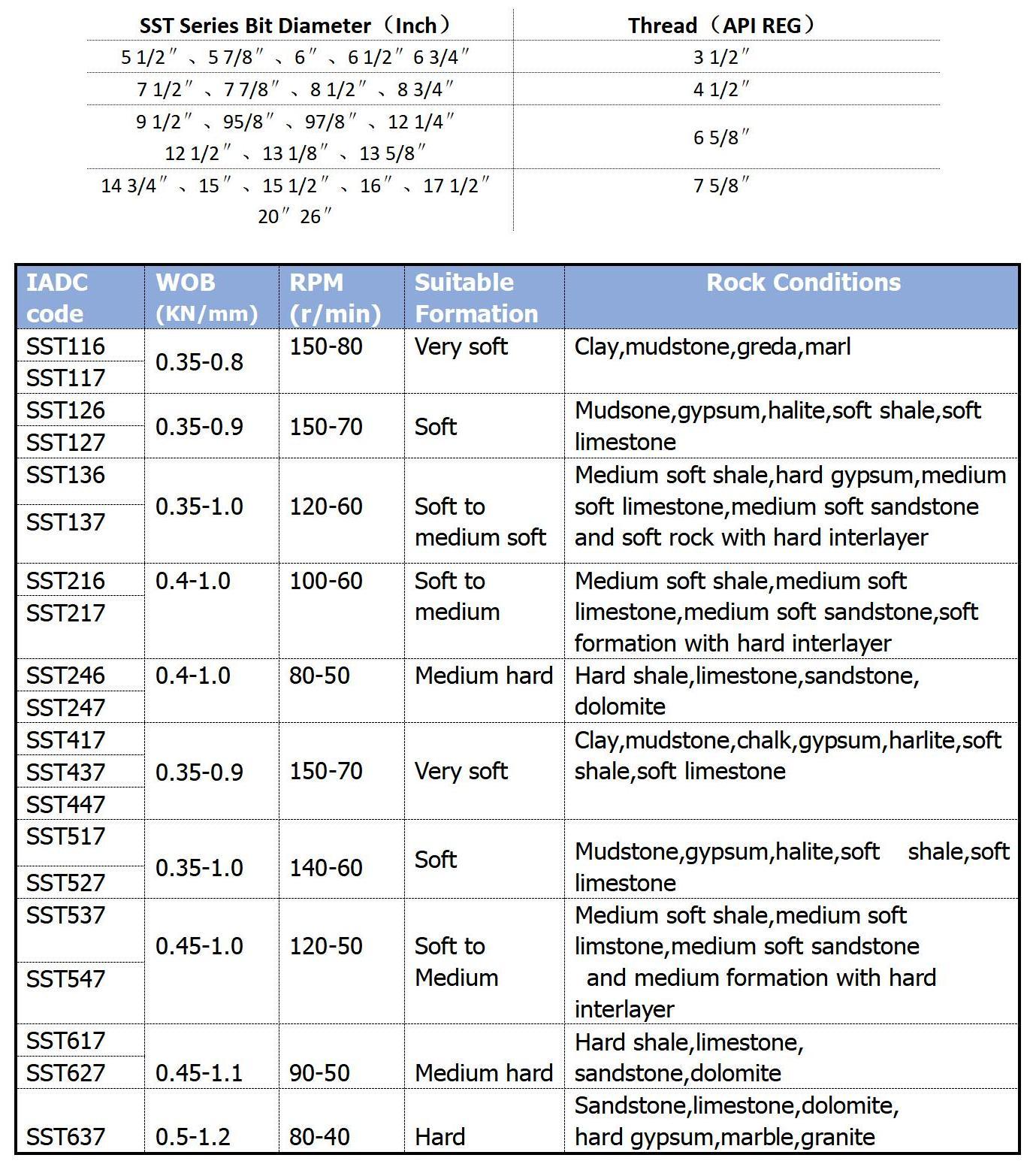

SST series bit sizes and operation parameters

Bearing Types and Main Applications

Rubber sealed roller bits main applications

- Adopted new alloy welding technology to improve abrasion and working life.

- Multiple gauge structure, weld trimming teeth on the edge to enhance gauge protection ability.

Metal sealed roller bits main applications

- Adopted high-speed bearing metal sealed technology, long working life under the screw drilling condition.

- High efficiency cutting edge and structure to improve drilling speed.

- Cutter shell self-protection shape to reduce abrasion of detritus and unbreakable rock.

- Best choice for directional well, horizontal drainhole and horizontal branch wells.

Urumqi Siruite Mechanical Equipment Co.,Ltd

Urumqi Siruite Mechanical Equipment Co.,Ltd