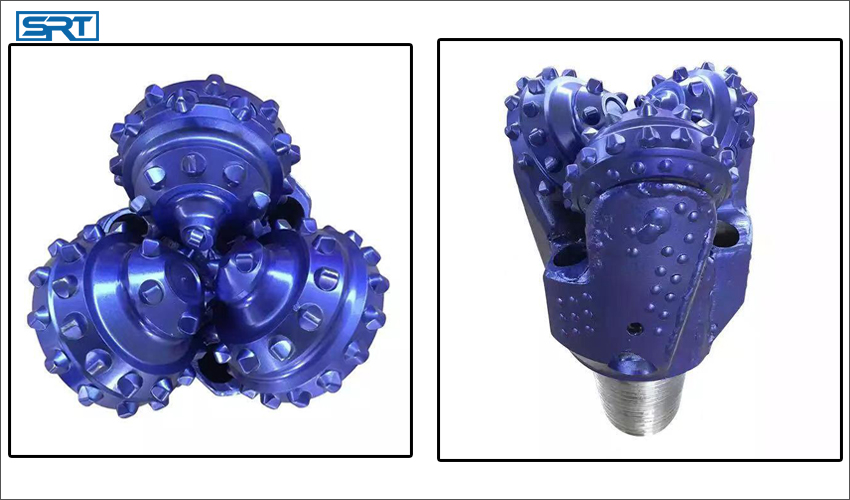

Product Description

SSH Series Three Roller Cone Bit

The SSH series tricone bit is widely used in borehole opening, exploration well and ore mining industry .itshould be implemented according to the specified operation procedure.Drill down well in the end,it is necessary to gently slow pressure (drilling pressure 5-15KN,speed 60R/min)run for half an hour before drilling at normal pressure.

Start the turntable on the condition of no pressure,the drilling pressure must be reduced before the drilling tools stop and lift the drill bit.In the process of drilling operation must be smooth,uniform drilling. found the bit bouncing and other abnormal conditions.should timely analysis and take effective measures.

152.4mm high speed drilling rock tricone button bits for underground water

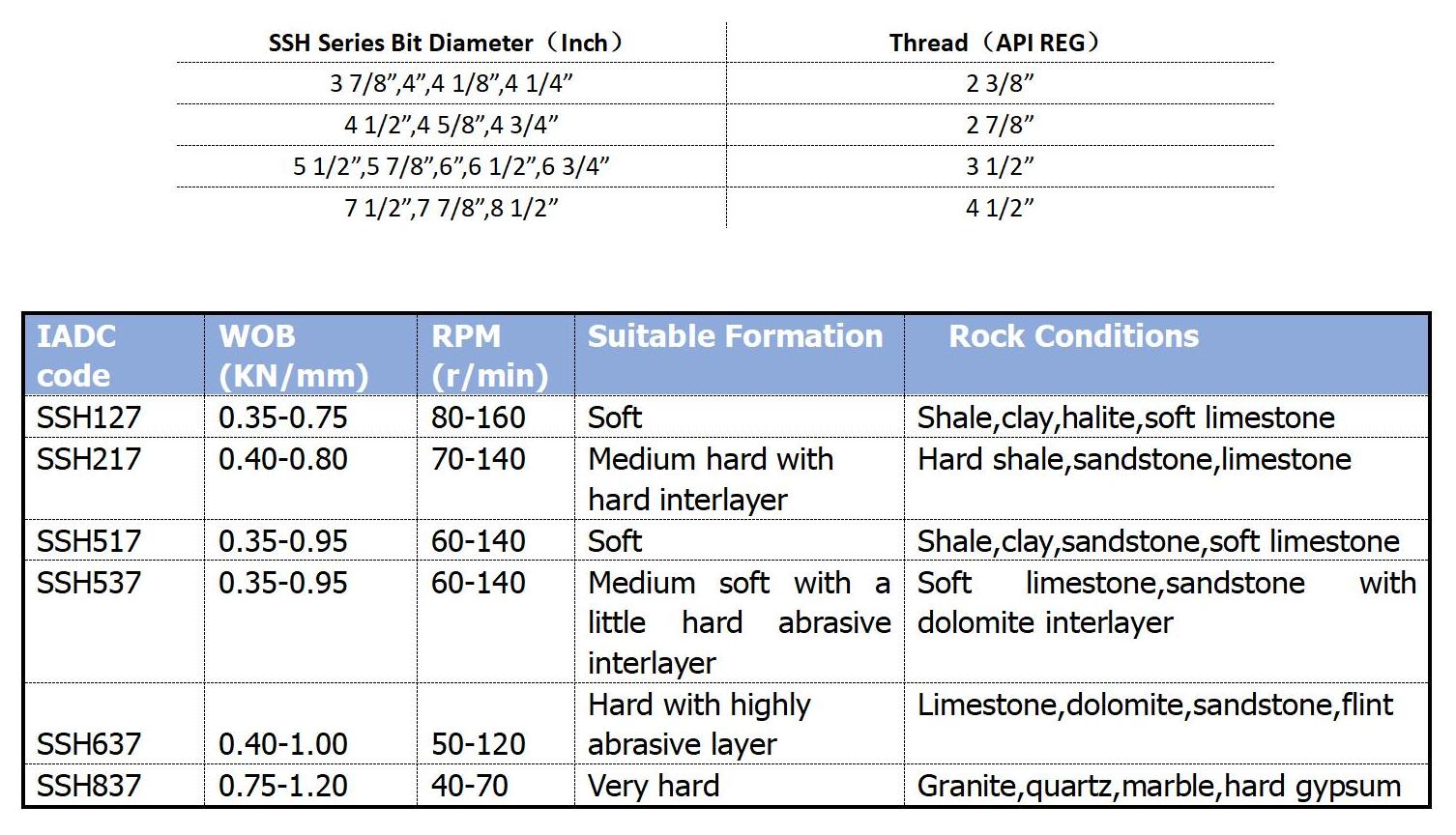

SSH series bit sizes and operation parameters

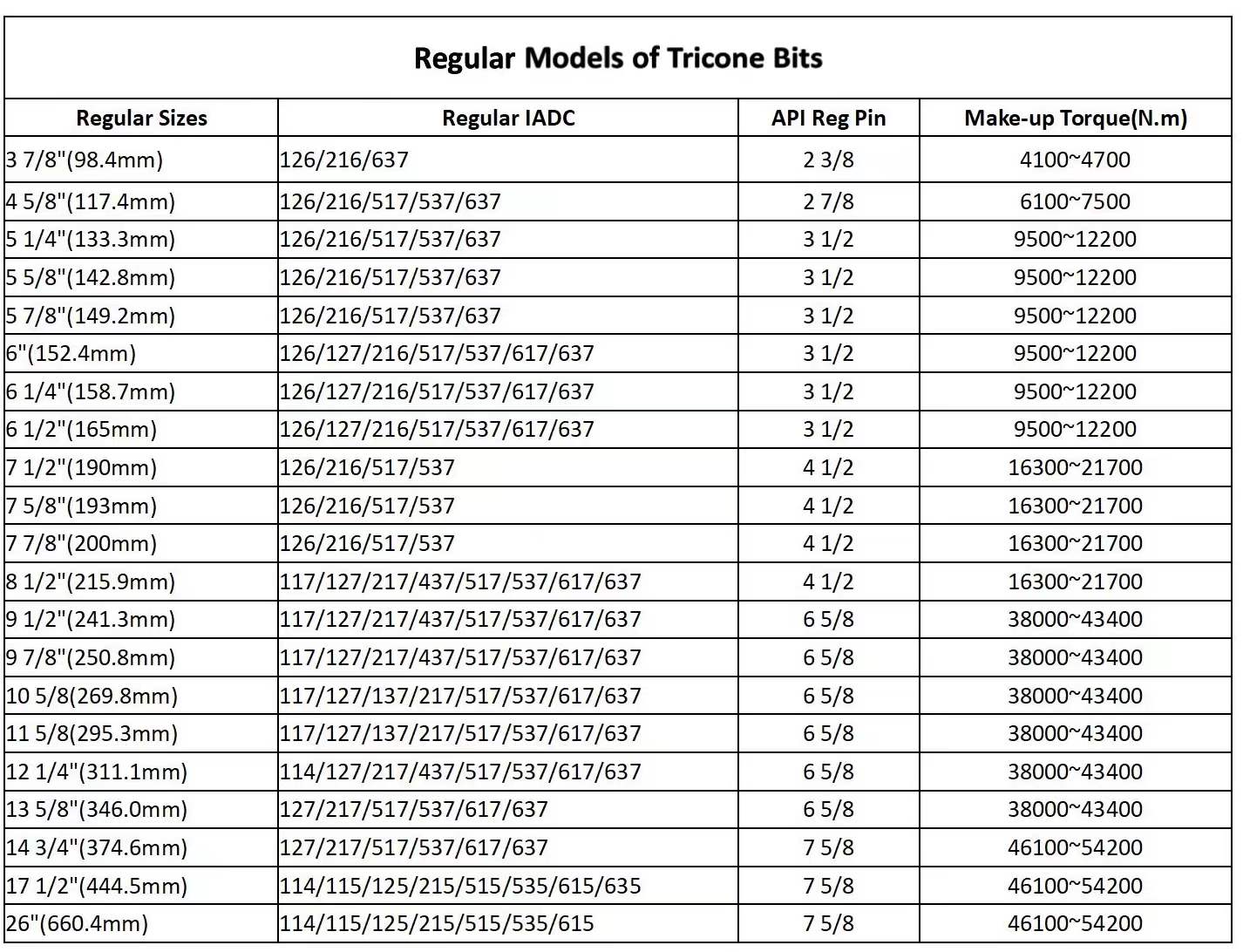

Siruite Tricone Bits Regulars Sizes

Operating Tricone Bit Instruction

The proper bit box should be chosen,according to the recommended prepaid moment of connected thread put into make-up torque,install the bit on the drill pipe or drill tools.be careful don't damage the bit or nozzle.

Regular the Meter before tripping in the hole. Make sure no obstacles in the well.

The operation should be stable,control speed to avoid bit impacting well wall.

When the bit is nearly close to well bottom,slow down the tripping speed, not to stop suddenly, to avoid bit impacting well bottom

when the bit is close to the well bottom,recycle the mud adequately and begin the rotate and down.

During operation,the applied WOB should be uniform,not to apply WOB discontinuously .if need to stop,the bit should be stop after the pointer return back.

How to choose suitable tricone rock bit

The suitable bits with higher cost performance is the most important.Such as, high class bits are not cost-effective for general water well drilling. Because the water well drilling rig can’t drive the supreme quality bits to perform their best.But for deep water drilling, first class rock bits are cost-effective though it’s worth more.When inquiring, Please tell us more details about your drilling project so that we can recommend best suitable bits for your reference.

Tricone Bit Instruction

Transporation :As the small volume of tricone bit and heavy weight,safety should be noticed during transportation.The package is carton or wooden case.Waterproof and damp proof should be noticed during transportation.

Storage:There is rubber piece and lubricating grease in tricone bit,So it can not be stored in the open air.and be damp proof. The temperature should be 0-40 centigrade degrees. No welding,heating and other processing is permitted on bit.

Validity :The roller bit should be utilized within four years after resembling.

Type Selection:Appropriate bit should be choosen according to drilling formation lithology and reference on the conjoint well.

Tricone bit working

(1)The proper bit box should be choosen,according to the recommended prepaid moment of connected thread put into make up torque,install the bit on the drill pipe or drill tools.be careful don’t damage the bit or nozzle.

Bit Specification(in)

5 7/8”~7 ½”

8”~9 3/8”

9 ½”~13 ¾”

Connected thread(in)

REG 3 ½”

REG 4 ½”

REG 6 5/8”

Recommended Torque(KN/M)

9.5~12.2

16.3~21.7

37.93~43.3

(2)Regular the Meter before tripping in the hole. Make sure no obstacles in the well.

(3)The operation should be stable,control speed to avoid bit impacting well wall.

(4)When the bit is nearly close to well bottom,slow down the tripping speed, not to stop suddenly, to avoid bit impacting well bottom.

(5)when the bit is nearly close to the well bottom,recycle the mud adequately and begin the rotate and down.

(6)During operation,the applied WOB should be uniform,not to apply WOB discontinuously .if need to stop,the bit should be stop after the pointer return back.

Tripping out of the hole

Under the normal situation,based on the experience or service time and wearing of the last bit,reference on the conjoint well,and the character of earth formation and bit.to choose the drill draw bake time.

In case of not exclusive or abnormal situation that results in accident. The bit should be drawn back in time.

Siruite Roller Bit Packages for Delivery

ATTN: We Can deliver drilling bits to over 100 countries and have been cooperating with long-term reliable international shipping agent for 12 years.No matter by sea,by air or by land, we could handle them all.

Urumqi Siruite Mechanical Equipment Co.,Ltd

Urumqi Siruite Mechanical Equipment Co.,Ltd