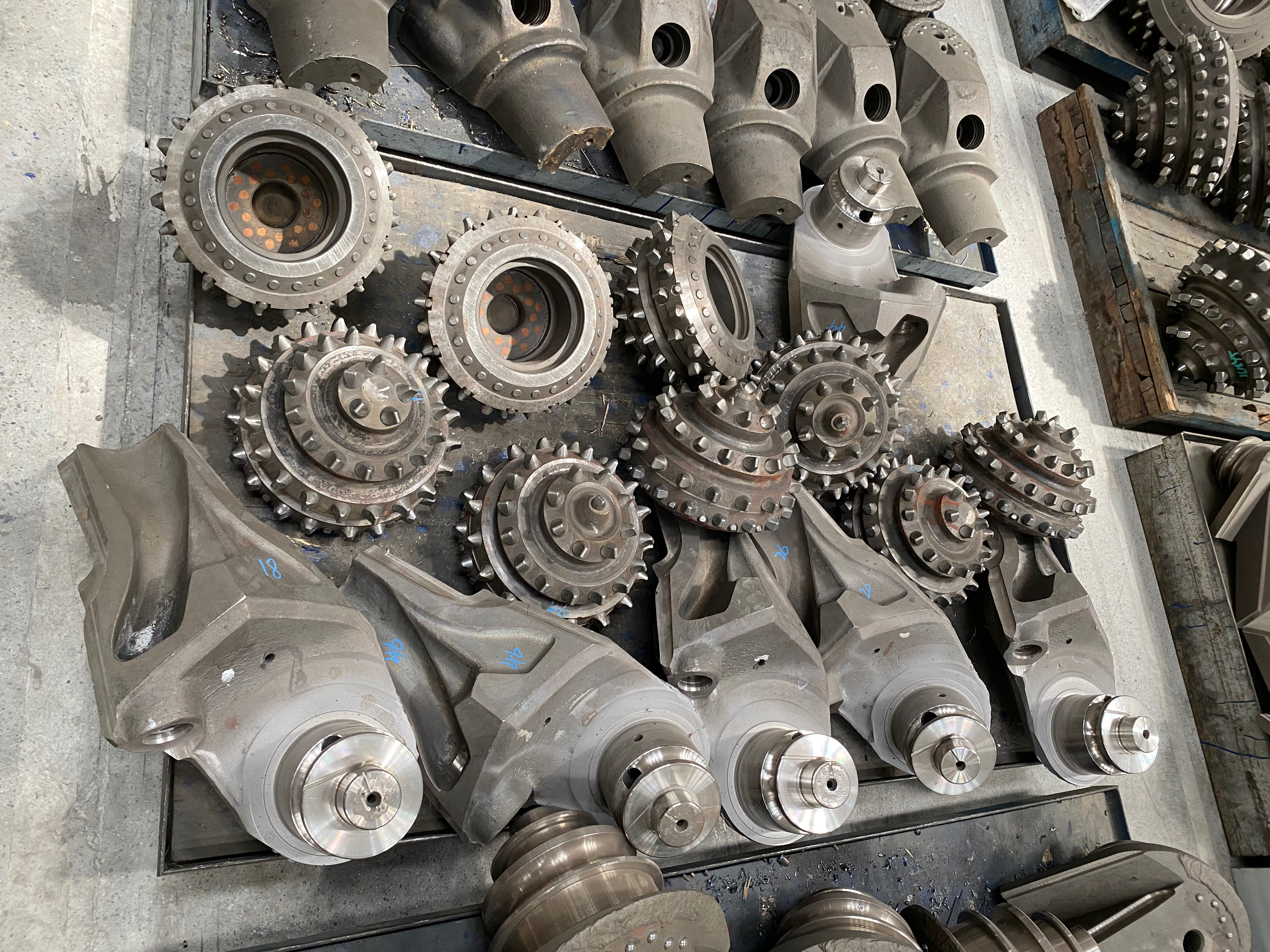

Siruite: Customization of Large Hole Openers for Tunneling

For projects like subways and gas pipeline construction, Siruite offers customization of large-size hole openers, specifically tailored for tunneling.

Key Aspects of Tunnel Engineering:

1.Geological & Hydrogeological Significance:

Tunnel projects predominantly exist underground, rendering the geology and hydrogeology crucial to the venture's success. A comprehensive geological survey is paramount, assessing rock properties, strength, stability, groundwater conditions, harmful gases, and geothermal metrics. These insights guide the selection of construction methods, equipment, and measures. Nevertheless, unexpected conditions might arise during construction due to geological complexities. To anticipate such scenarios, techniques like test guide pits, horizontal drilling, and acoustic detections are employed to monitor and adapt to changing conditions.

2.Challenging Underground Environment:

The subterranean working environment can be tough, potentially deteriorating due to factors like harmful gas from blasts. To combat this, measures including artificial ventilation, lighting enhancements, dust control, soundproofing, and drainage are vital. This ensures worker well-being and efficient productivity.

3.Future-proof Construction:

Given that underground tunnels are permanent structures, it's essential to meticulously plan and design them. Once constructed, modifications become challenging, if not impossible. The aim is to build with foresight, eliminating future complications. A silver lining, however, is that tunnel construction is not impeded by day-night cycles, seasonal changes, or varying climatic conditions.

4.Unique Construction Dynamics:

Tunnels typically have a linear structure with just two primary work fronts - the entrance and the exit. This implies that tunneling can be a slow process with extended timelines. To expedite this, auxiliary structures like vertical shafts or horizontal holes are used. Given the tunnel's confined space, sequential work is often the norm, with some processes happening in parallel. Effective management, organized planning, and careful equipment and pipeline layout become essential. The machinery used for tunnel construction must be robust yet compact.

5.Remote and Inaccessible Construction Sites:

Many tunnels traverse mountains, leading to construction sites being in remote, inaccessible areas. This often translates to logistical challenges, from transportation woes to supply issues. Such considerations must be front and center when tunnel projects are being planned.

Selecting the Ideal Tunnel Drill Bit:

Siruite, standing tall as one of China's leading drill bit manufacturers, proudly offers its advanced tunnel drill bits at competitive rates. We invite you to opt for our tungsten carbide insert teeth roller cutters and hob cutters hole opener reamer bits, ensuring impeccable drilling quality and safety.

URUMQI SIRUITE MECHANICAL EQUIPMENT CO., LTD

URUMQI SIRUITE MECHANICAL EQUIPMENT CO., LTD