SSJ Series Tricone Drill Bit

SSJ series bit uses the most advanced sealing technology in the world. i.e. the metal face seal (MFS). It can perform consistently in high speed drilling applications, and the ideal tool for drilling directional and horizontal wells and deep oil well. In comparison with conventional rubber O-ring sealed bits, the average working life (total drilling hours) of SSJ series bit under the condition of the same operating parameters can be increased by 35%. So if you need to drill ultra deep and high speed, metal sealed bearing tricone bits are your best choice. compared to USA Hughes and Smith bits,kingdream bits have same drilling performance but competitive price.

Rotary Rock Drill Tricone Roller Bits Drilling Environments

How to choose suitable tricone rock bit

Formation Type: Understand the type of formation you will be drilling into. Different formations require specific tricone bit designs and cutting structures. For example, soft formations may benefit from a bit with large, widely spaced teeth, while hard formations may require a bit with smaller, closely spaced teeth.

Bearing Type: Tricone bits come with different bearing types, including journal bearings and sealed roller bearings. Journal bearings are cost-effective but less durable, while sealed roller bearings offer better performance and longevity. Choose a bearing type that suits your drilling conditions and budget.

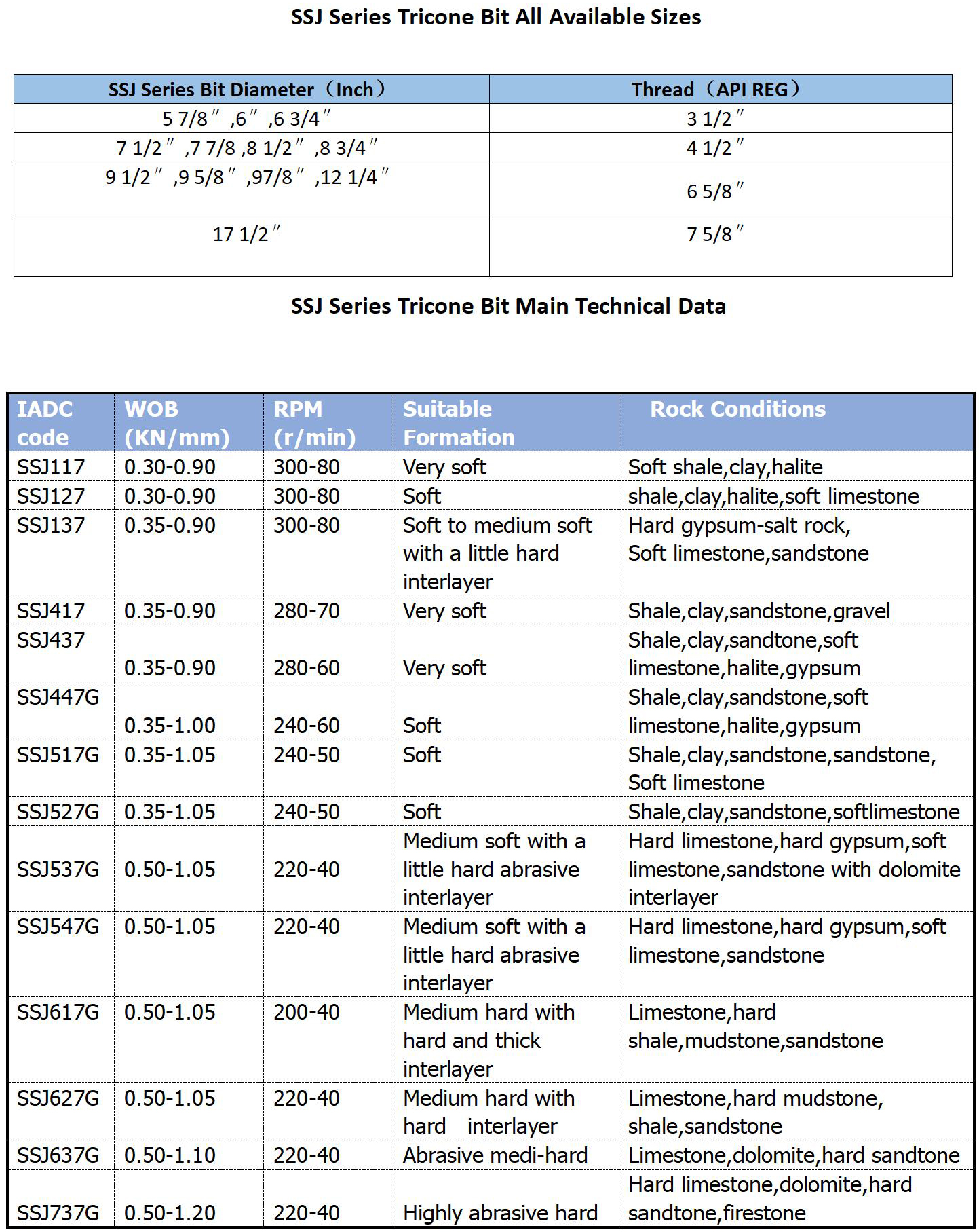

Bit Size and Connection: Consider the required bit size and connection type. The bit size should match your drilling requirements, and the connection should be compatible with your drilling rig's specifications.

Tooth Type: Tricone bits can have different tooth types, such as milled tooth or tungsten carbide inserts (TCI). Milled tooth bits are suitable for softer formations, while TCI bits are more effective in harder formations. Evaluate the formation hardness to determine the appropriate tooth type.

Gauge Protection: Check if the tricone bit has adequate gauge protection. The gauge refers to the outer edge of the bit, which is prone to wear and damage. Enhanced gauge protection helps prolong the bit's lifespan and maintain stability during drilling.

Brand Reputation: Consider the reputation and reliability of the tricone bit manufacturer. Reputable brands often provide high-quality, durable bits that deliver consistent performance.

Budget: Set a budget for your tricone bit purchase. While it's essential to find a cost-effective option, prioritize quality and performance over the lowest price. Investing in a durable bit can save you money in the long run.

Transporation:As the small volume of tricone bit and heavy weight,safety should be noticed during transportation.The package is carton or wooden case.Waterproof and damp proof should be noticed during transportation.

Storage:There is rubber piece and lubricating grease in tricone bit,So it can not be stored in the open air.and be damp proof. The temperature should be 0-40 centigrade degrees. No welding,heating and other processing is permitted on bit.

Validity:The roller bit should be utilized within four years after resembling.

Type Selection:suitable bit should be choosen according to drilling formation lithology and reference on the conjoint well.

Siruite Roller Bit Packages for Delivery

Urumqi Siruite Mechanical Equipment Co.,Ltd

Urumqi Siruite Mechanical Equipment Co.,Ltd