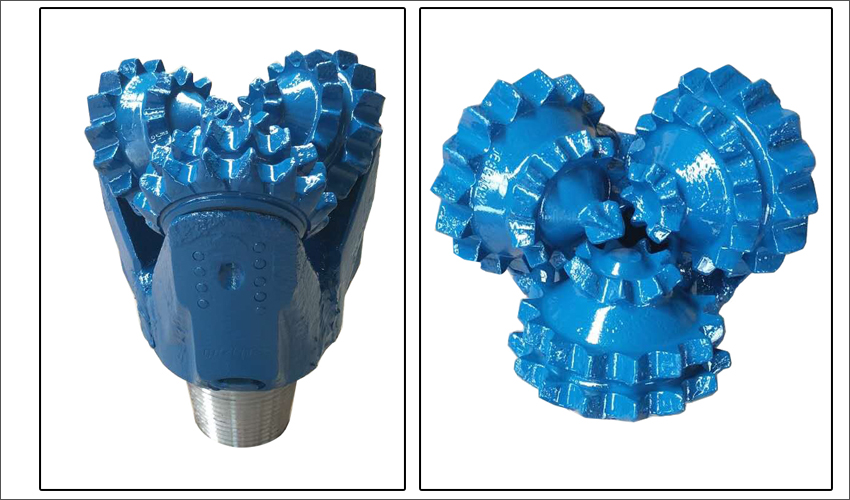

SSH Series Three Roller Cone Bit

The SSH series tricone bit is widely used in borehole opening, exploration well and ore mining industry .itshould be implemented according to the specified operation procedure.Drill down well in the end,it is necessary to gently slow pressure (drilling pressure 5-15KN,speed 60R/min)run for half an hour before drilling at normal pressure.

Start the turntable on the condition of no pressure,the drilling pressure must be reduced before the drilling tools stop and lift the drill bit.

In the process of drilling operation must be smooth,uniform drilling. found the bit bouncing and other abnormal conditions.should timely analysis and take effective measures.

190mm close bearing metal teeth tricone rock bits for soil rock drilling

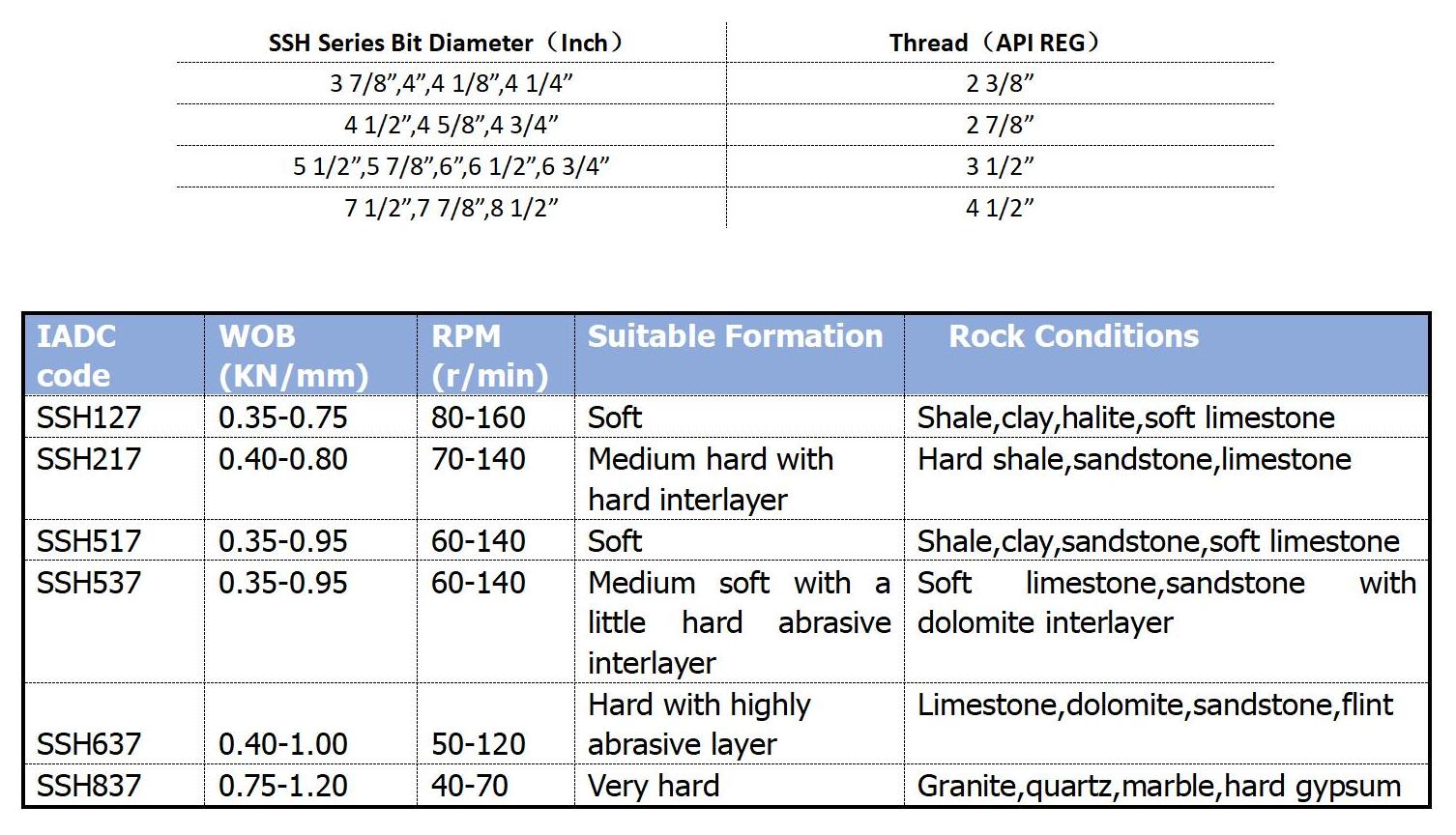

SSH series bit sizes and operation parameters

Related Small Size Rotary Rock Roller Bit

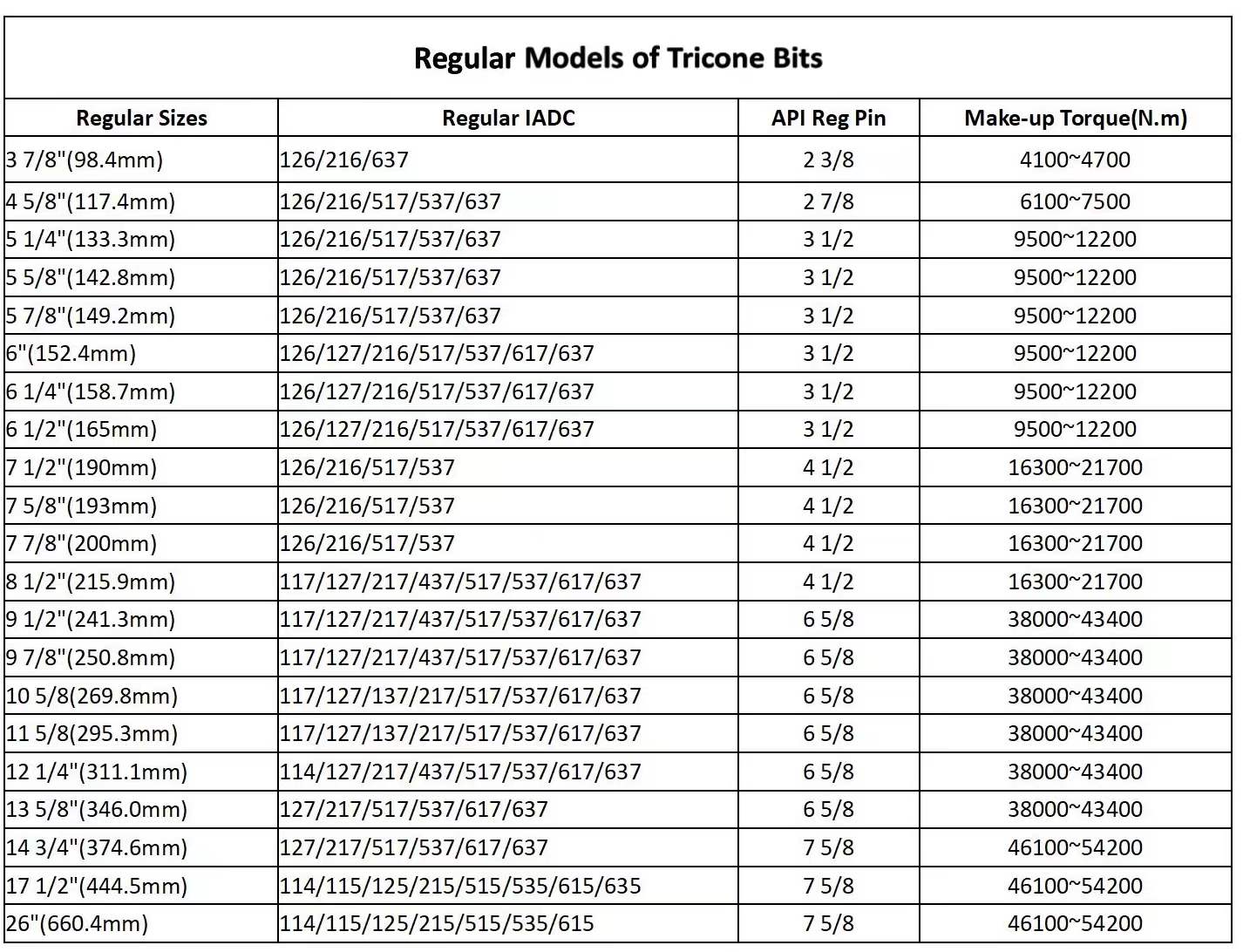

Siruite Tricone Bits Regulars Sizes

Operating Tricone Bit Instruction

The proper bit box should be chosen,according to the recommended prepaid moment of connected thread put into make-up torque,install the bit on the drill pipe or drill tools.be careful don't damage the bit or nozzle.

Regular the Meter before tripping in the hole. Make sure no obstacles in the well.

The operation should be stable,control speed to avoid bit impacting well wall.

When the bit is nearly close to well bottom,slow down the tripping speed, not to stop suddenly, to avoid bit impacting well bottom

when the bit is close to the well bottom,recycle the mud adequately and begin the rotate and down.

During operation,the applied WOB should be uniform,not to apply WOB discontinuously .if need to stop,the bit should be stop after the pointer return back.

How to choose suitable tricone rock bit

Formation Type: Understand the type of formation you will be drilling into. Different formations require specific tricone bit designs and cutting structures. For example, soft formations may benefit from a bit with large, widely spaced teeth, while hard formations may require a bit with smaller, closely spaced teeth.

Bearing Type: Tricone bits come with different bearing types, including journal bearings and sealed roller bearings. Journal bearings are cost-effective but less durable, while sealed roller bearings offer better performance and longevity. Choose a bearing type that suits your drilling conditions and budget.

Bit Size and Connection: Consider the required bit size and connection type. The bit size should match your drilling requirements, and the connection should be compatible with your drilling rig's specifications.

Tooth Type: Tricone bits can have different tooth types, such as milled tooth or tungsten carbide inserts (TCI). Milled tooth bits are suitable for softer formations, while TCI bits are more effective in harder formations. Evaluate the formation hardness to determine the appropriate tooth type.

Gauge Protection: Check if the tricone bit has adequate gauge protection. The gauge refers to the outer edge of the bit, which is prone to wear and damage. Enhanced gauge protection helps prolong the bit's lifespan and maintain stability during drilling.

Brand Reputation: Consider the reputation and reliability of the tricone bit manufacturer. Reputable brands often provide high-quality, durable bits that deliver consistent performance.

Budget: Set a budget for your tricone bit purchase. While it's essential to find a cost-effective option, prioritize quality and performance over the lowest price. Investing in a durable bit can save you money in the long run.

Transporation:As the small volume of tricone bit and heavy weight,safety should be noticed during transportation.The package is carton or wooden case.Waterproof and damp proof should be noticed during transportation.

Storage:There is rubber piece and lubricating grease in tricone bit,So it can not be stored in the open air.and be damp proof. The temperature should be 0-40 centigrade degrees. No welding,heating and other processing is permitted on bit.

Validity:The roller bit should be utilized within four years after resembling.

Type Selection:Appropriate bit should be choosen according to drilling formation lithology and reference on the conjoint well.

Siruite Roller Bit Packages for Delivery

Urumqi Siruite Mechanical Equipment Co.,Ltd

Urumqi Siruite Mechanical Equipment Co.,Ltd